We strictly control every work procedure to produce PA6 colored yarn from polymerization, spinning, texturizing, and two for one twisting, yarning, coloration and doffing, which ensures the high quality.

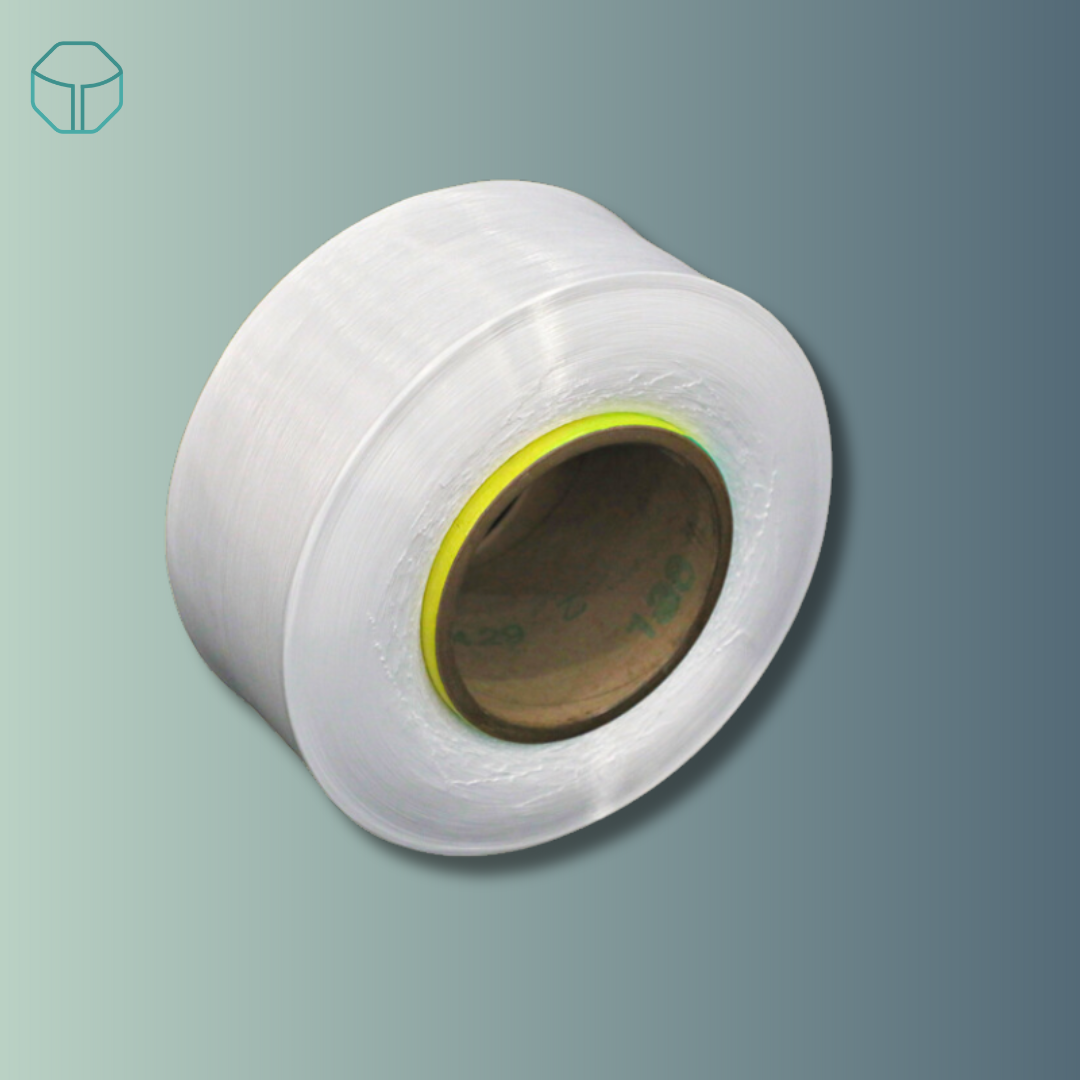

Tiantex is the special dyeing plant for dyeing nylon 6 and nylon 66 DTY. The factory owns more than 20 dyeing batches in various volume, from 1kg especially for samples to 500kg which make sure of the little batch difference for orders of big quantity. The daily output is 20 MT at present. All processes of dyeing nylon yarns are finished on its own, including polymerization- spinning- texturizing- twisting- shape dyeing- winding packing. Each process is closely monitored and controlled. That’s unique in the domestic nylon manufacturing industry. The factory has popular colors and specifications in stocks like 40D/2, 50D/2, 70D/2, 100D/2, red nylon, black nylon, white nylon etc. The most authorized certificate— OEKO TEX STANDARD 100 is obtained. The factory guarantee its dyeing yarns are environmental protection, no harm to human beings with direct touch to skins.

Tiantex is the lead in realization of the colour norm and joinless length-fixing, through the product innovation and upgrading and application of the word advanced colour-check system, promises to deliverly within 3 days for domestic customers, set up a news standard for the industry and strives to create NO.1 brand and No.1 scale for China. Yearly output capacity stands at 25000 tons.